5 Tips for Maintaining Your Dump Trailer to Ensure Optimal Performance

Dump trailers are essential for many businesses and individuals in the construction, landscaping, and agricultural industries. They transport large amounts of materials, including dirt, gravel, and other debris. While dump trailers are handy, they require regular maintenance to ensure they are in good working condition and perform optimally. Here are five tips to help you maintain your dump trailer and ensure it runs at its best.

1. Inspect the Trailer Regularly

The first step in maintaining your dump trailer is to inspect it regularly. This includes checking the frame, axles, tires, and other components for signs of wear and tear. Look for any cracks, rust, or further damage that could cause the trailer to malfunction. Additionally, check the trailer’s fluid levels and make sure they are topped off as needed.

2. Clean the Trailer

Cleaning your dump trailer is a crucial part of its maintenance. This will help prevent rust and corrosion, leading to premature wear and tear. Use a pressure washer to remove dirt, debris, and grime from the trailer’s exterior. You should also use mild detergent to clean the trailer’s interior, including the bed and sides.

3. Lubricate the Moving Parts

Lubricating the moving parts of your dump trailer is essential for its proper functioning. This includes the axles, wheels, and other components. Use a high-quality lubricant to ensure the parts are correctly lubricated and to prevent them from becoming dry and corroded. The frequency of greasing trailer axles depends on a few factors, including the type of axle, the load capacity of the trailer, and the operating conditions. However, as a general rule of thumb, it is recommended to grease the trailer axles every 12 months or 12,000 miles, whichever comes first.

However, if the trailer is used frequently or operates in harsh conditions such as dusty, dirty, or wet environments, it may require more frequent greasing. In this case, inspecting the trailer axles periodically is a good practice to determine if they need to be greased sooner.

It’s important to note that greasing trailer axles is critical for maintaining the longevity and performance of the trailer. Properly lubricated axles reduce friction and wear, preventing premature failure and costly repairs.

If you need clarification about the frequency of greasing your trailer axles, consult the owner’s manual or contact the manufacturer for specific recommendations. Always consult the manual first to ensure this article matches your particular trailer. Regular maintenance and greasing of the trailer axles can help ensure your trailer operates smoothly and safely for years.

4. Check the Brakes

The brakes on your dump trailer are essential for its safe operation. Make sure to check the brakes regularly to ensure they are functioning properly. If the brakes are not working correctly, they should be replaced immediately. Trailer electric brakes operate through an electric brake controller that is mounted inside the towing vehicle. When the driver applies the brakes, the controller sends an electric signal to the brakes on the trailer, activating to slow down or stop the trailer.

The electric brake controller has several settings that can be adjusted to control the amount of braking force applied to the trailer. This is important because different trailers have different weights and require different amounts of braking force to slow down or stop.

The electric brake system consists of several key components:

- Brake controller: This device sends an electric signal to the trailer brakes when the driver applies the brakes.

- Brake actuator: This is the mechanism that applies the brakes on the trailer when the brake controller receives the electric signal.

- Brake assemblies: These are the actual brakes mounted on the trailer wheels and activated by the brake actuator.

- Brake wiring: Connect the brake controller to the brake actuator and trailer brake assemblies.

When the driver applies the brakes in the towing vehicle, the brake controller sends an electric signal to the brake actuator on the trailer. The brake actuator then activates the brake assemblies on the trailer wheels, which slows down or stops the trailer.

Electric brakes are typically more reliable and efficient than hydraulic brakes, which require a hydraulic system. Additionally, electric brakes allow for more precise control of the braking force applied to the trailer, which can help prevent skidding and improve safety. However, it’s important to note that trailer electric brakes require regular maintenance and inspection to operate appropriately. If you need clarification on the condition of your trailer’s electric brakes, consult the owner’s manual or contact a professional for inspection and repair.

5. Check the Lights

The lights on your dump trailer are also crucial for its safe operation. Make sure to check the lights regularly to ensure they are working correctly. If the lights are not working, they should be replaced immediately.

Following these five tips ensures your dump trailer is in good working condition and performs optimally. Regular maintenance is essential for your trailer’s safety and performance, so inspect it regularly and take the necessary steps to keep it in top shape.

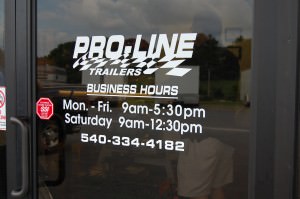

Looking for parts? Need guidance? Check out the Pro-line Trailers online parts department here.