8 Tips to Help You Maintain a Heavy Equipment Trailer

Did you know there are over 1.7 million heavy equipment trailers across the country? These trailers can weigh up to 16,000 pounds and transport heavy items like automobiles and construction materials. For this reason, it is vital to maintain your equipment and get regular maintenance checks.

To help out truck drivers and owners alike, we’ve compiled some tips below on how you can maintain your heavy equipment trailer more efficiently.

1. Check the Air

If you see the trailer tires are flat or even squishy, that means they’re under-inflated. If it happens on one tire only, that’s probably no big deal because chances are it has an internal problem like a plugged valve stem.

But if you have multiple tire pressure drops simultaneously, your flatbed trailers might have an unseen leak somewhere in their air system. It needs to be taken out to service for repairs.

Air leaks can damage tires quickly by causing them to overheat and delaminate, so this is serious business. Make sure all valves are closed before pumping up tires! When filling with air, always hold the compressor’s gauge close to the fill valves so you can read the pressure as you go.

The last step is inspecting all hose fittings for cracking, chafing, or seal leakage signs. They can allow moisture and dirt into the air system.

2. Inspect Suspensions

While it’s not always possible to do a full pre-trip suspension inspection on every trailer, checking for loose or missing bolts and nuts is an excellent place to start.

Uneven tire wear indicates that the suspension is out of alignment.

A quick way to check for excessive movement in the suspension is to grab hold of one of the axle hubs and try to wiggle it side-to-side. There should be very little play if the suspension is in good working order.

Suspension parts eventually wear out and need to be replaced. Yet, identifying worn-out parts before they cause a breakdown is important.

3. Lube it Correctly

Chances are you already know that sticking your fingers in the grease fittings on your trailer axles is not a good idea. Few people realize that axle grease needs annual replacement depending on how much the trailer is used.

When grooves in the race dry up, it can allow dirt and moisture into bearings, which causes damage. Grease also gets fluid-like under higher temperatures. This way, cold weather use will require thicker lubes with lots of tackiness for improved bearing lubrication.

If you’re using a mobile food service trailer for catering events, look for greases designed to handle the fluctuating temperatures and high moisture levels.

4. Take Time for Brakes

Like any other vehicle, landscaping trailers and gooseneck trailer brakes need periodic inspections and maintenance. This creates a safe environment for drivers and other cars on the road.

With your parking brake engaged, grab each brake shoe one at a time and try to rock it back and forth to see if there’s any play or stutter in its movement. Rocking just one side should produce equal resistance from that brake drum.

A trailer brake controller is a must-have for any vehicle that tows a trailer. This device helps to disperse the braking force between the tow vehicle and the trailer, which helps prevent any skidding or jackknifing.

Yet, if you notice uneven resistance while rocking both sides, it could indicate an improper adjustment or potential damage. Even worse, dragging brakes can lead to complete failure. Thus, it’s a good idea to give them a quick check before every trip.

5. Keep it Clean

Keeping your tilt trailers clean may seem like an unnecessary chore, but it’s essential for several reasons. Not only does a clean trailer look nicer, but it also helps you catch minor problems before they turn into big ones.

Trailer frames and running gear can quickly corrode if not regularly washed and dried. Therefore, don’t neglect this vital step!

Check seams, welds, and bolts for signs of rust and corrosion. Speaking of bolts, a regular check on all your trailer nuts and bolts is vital, especially after major repairs or modifications.

You should also have a safety chain or strap attached between the two trailers so that the load on one doesn’t cause both trailers to tip over. If possible, avoid using your heavy equipment trailer for too much work before it’s had time to cool down. Otherwise, you could warp or damage the trailer frame.

6. Make Sure it Is Lighting Up Properly

One of the most important things to check on your trailer before every trip is its lighting system. All trailers are required by law to have front and rear reflectors and working tails, brakes, and directional lights.

If any of your trailer’s lights are not working, it could result in a ticket or, worse, an accident. Therefore, make it a habit to check them every time you hit the road.

Also, check the wiring system regularly for any signs of wear and tear. Damaged wiring can lead to fires or other electrical problems down the road.

7. Protect the Trailer Body Against Corrosion

Utility trailers are often exposed to harsh weather and corrosive elements. This can take its toll on the metal body of the trailer over time. So, it’s essential to take some preventative steps to protect it.

One way to do this is by using a quality trailer wax or sealant. This will help create a barrier against the elements and make it easier to clean up any dirt or debris.

You can also buy special corrosion-inhibiting sprays and coatings that’ll help keep your trailer looking new for years to come!

8. Properly Align the Hitch

If your hitch isn’t properly aligned, it can cause many problems with your towing experience. The trailer might sway from side to side, or you might have trouble steering the vehicle. You should have the hitch adjusted if it’s not aligned correctly.

If there is any damage present, have it repaired as soon as possible. A damaged hitch can lead to more significant problems down the road and even cause an accident.

Get the Best Heavy Equipment Trailer Parts and Services Now

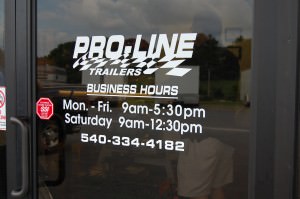

Do you run a logistic company and have several utility trailers or open gooseneck trailers that need regular maintenance and need a reliable service center? At ProLine Trailers, we service, repair, sell OEM parts and sell used trailers at affordable rates.

Whether you want to shop for heavy equipment trailer parts or schedule service, we’ve got you covered. Please get in touch with us today to schedule a maintenance service.